MAITEWEI

Tungsten and molybdenum material suppliers

Application and technological innovation of tungsten and molybdenum accessory products

MAITEWEI

Processing of tungsten and molybdenum materials

Dedicated to technological innovation in the field

MAITEWEI

Tungsten and molybdenum material suppliers

Application and technological innovation of tungsten and molybdenum accessory products

ABOUT US

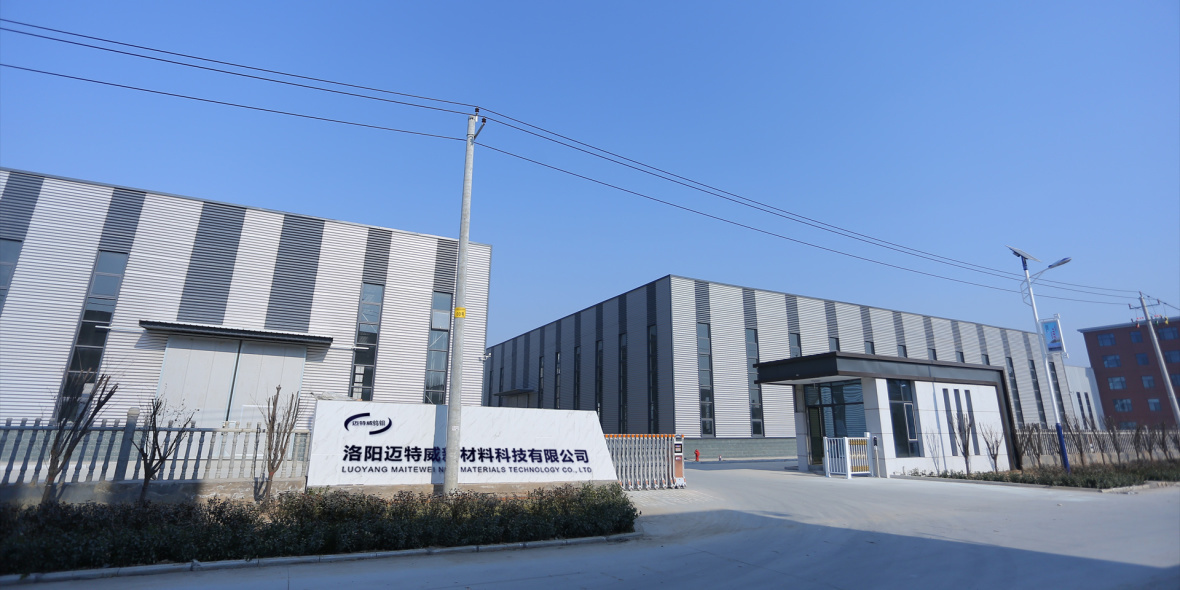

Luoyang Matvey New Material Technology Co., Ltd.

Luoyang Matway New Material Technology Co., Ltd. is an emerging technology enterprise in the industry. It is located in Dongmagou Industrial Agglomeration Area, Luoyang District, China (Henan) Pilot Free Trade Zone, Henan Pilot Free Trade Zone, covering an area of 60 mu and a workshop area of 23500 ㎡.

Luoyang Matvey Tungsten and Molybdenum New Material Technology Co., Ltd. has established a professional research and development organization. Many research centers in Henan Province carry out product upgrading and research and development. New product development project of new monocrystalline silicon furnace with long life tungsten and molybdenum new material; Research and development of thermal field of sapphire long crystal furnace with long life and large capacity; Research and development of new radiation resistant, large size and fine crystal tungsten and molybdenum alloy sputtering target), the project of "development and application of tungsten molybdenum alloy with self-generated ceramic particles" participated in in 2023 was recognized by technical experts in Henan Province; the project of "key preparation technology and application of high-performance multiphase tungsten alloy" participated in in 2023 was recognized by the industry.

Product

Recommend

-

[object Object],[object Object],[object Object],[object Object],[object Object],[object Object]

-

Molybdenum target

Molybdenum target is an industrial material, widely used in conductive glass, STN/TN/TFT-LCD, optical glass, ion coating and other industries, applicable to all flat coating and rotary coating system.

[object Object],[object Object],[object Object],[object Object],[object Object],[object Object]

-

Molybdenum wire ring

Molybdenum wire ring is a tool that can measure surface roundness and straightness. It uses the elasticity of molybdenum wire to detect surface deviation. By reading the scale on the molybdenum wire ring, the deviation of the measured surface can be judged. Molybdenum wire rings are often used to measure the deviation of the inner diameter of the cylinder block.

[object Object],[object Object],[object Object],[object Object],[object Object],[object Object]

-

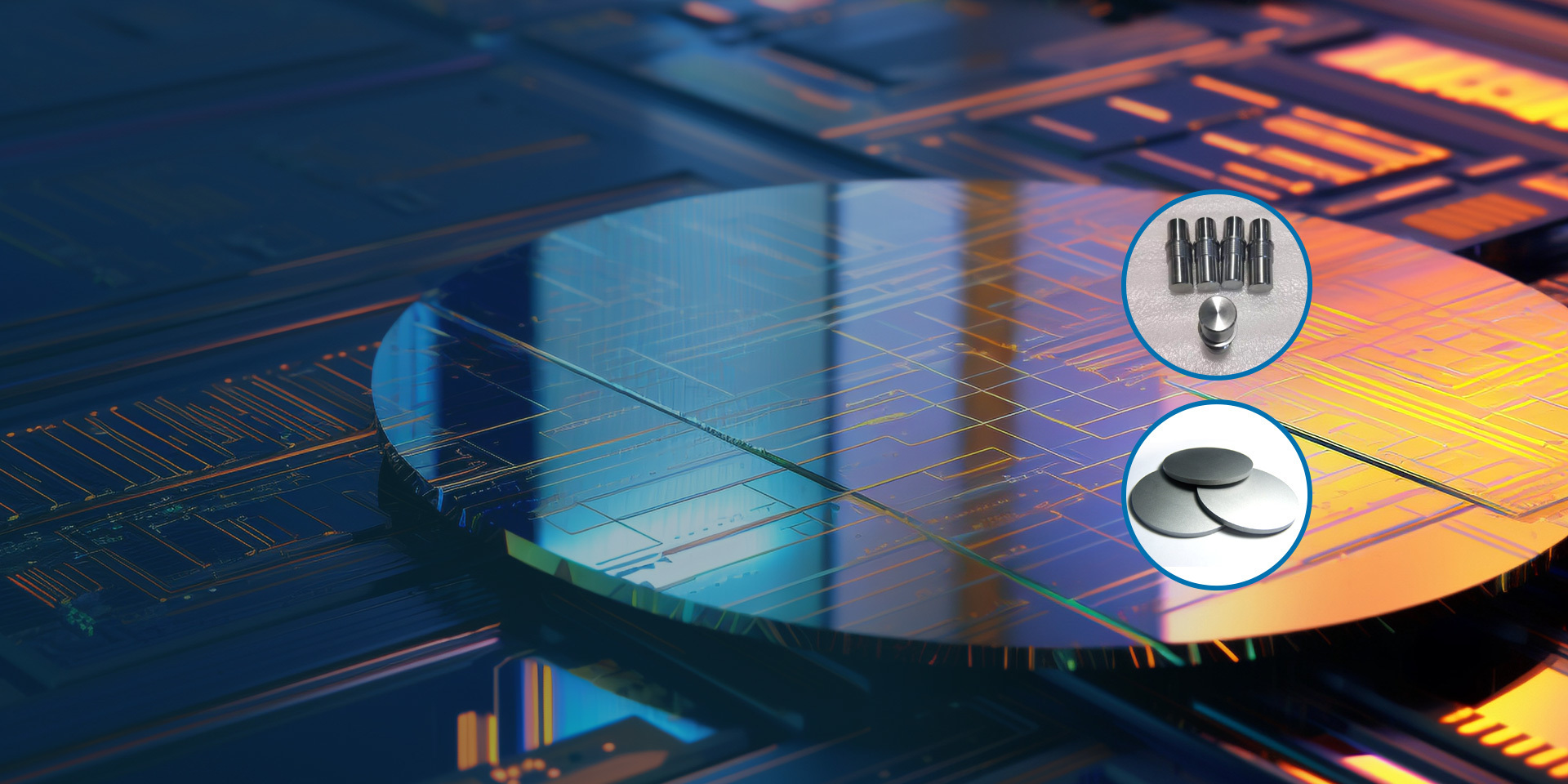

Molybdenum wafer

Molybdenum circle has the characteristics of good electrical and thermal conductivity, high strength, small thermal expansion coefficient and good processing performance. It is an indispensable substrate material for the production of silicon rectifier complete sets of equipment and semiconductor silicon devices. The chemical composition of the molybdenum wafer is stable, the molybdenum content is as high as 99.9%, the size is accurate, the surface roughness is low, and the surface roughness can reach below Ra≤ 1.6μm.

[object Object],[object Object],[object Object],[object Object],[object Object],[object Object]

-

Tungsten rod

Tungsten rod (English name: Tungsten Bar) is also called tungsten alloy rod. Tungsten alloy rods (WMoNiFe) and Anviloy 1150 are made of metal powder at a specific high temperature, using special high-temperature powder metallurgy technology. This tungsten alloy rod material has a low coefficient of thermal expansion, good thermal conductivity and good material properties.

[object Object],[object Object],[object Object],[object Object],[object Object],[object Object]

-

Tungsten crucible

Tungsten crucible (English name: Tungsten Crucibles) is one of the metal tungsten products, mainly divided into sintering molding (applied to powder metallurgy technology), stamping molding, spinning type. The use of tungsten rod turning molding (general size is relatively small), welding molding a variety of pure tungsten plate, tungsten and pure tungsten rod by the corresponding process. The tungsten crucible can be used in a vacuum inert gas at 2600 degrees or less. Tungsten has high melting point and boiling point, good high temperature strength, wear resistance and corrosion resistance, high thermal conductivity, small thermal expansion coefficient, and good hardenability. Tungsten crucible is widely used in rare earth smelting, quartz glass, electronic spraying, crystal growth and other industries.

[object Object],[object Object],[object Object],[object Object],[object Object],[object Object]

-

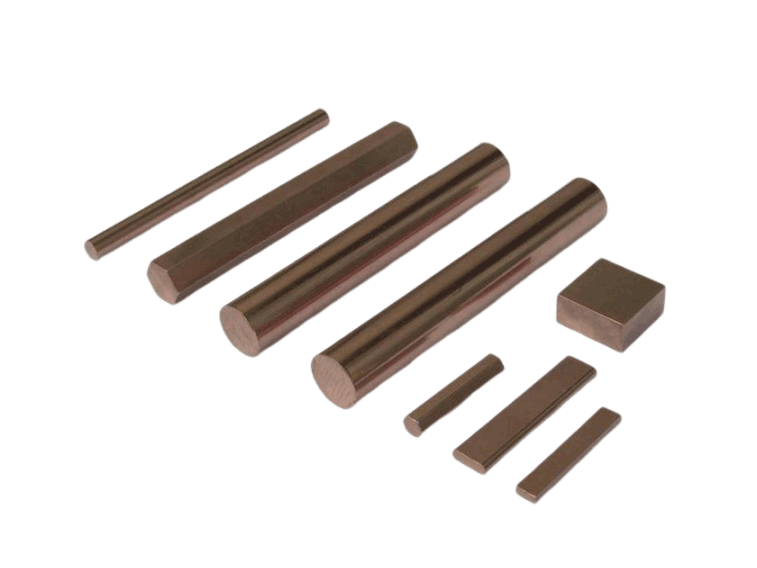

Tungsten copper alloy

Tungsten copper alloy is an alloy composed of tungsten and copper. The copper content of commonly used alloys is 10% to 50%. The alloy is made by powder metallurgy method, which has good electrical and thermal conductivity, good high temperature strength and certain plasticity. At very high temperatures, such as above 3000 ℃, the copper in the alloy is liquefied and evaporated, absorbing a large amount of heat and reducing the surface temperature of the material, so this kind of material is also called metal sweating material. Tungsten copper alloy has a wide range of uses. It is mainly used to manufacture high-voltage electrical switch contacts and rocket nozzle throat lining, tail rudder and other high-temperature components that resist arc ablation. It is also used as an electrode for electrical processing, high-temperature molds and other occasions that require high electrical and thermal conductivity and high-temperature use.

Technical strength

Assurance

Patent technology

Equipments

Digital pressure Sensor

Technical

technical support

Quality Assurance

Multiple research centers are conducting product upgrades and research and development

Equipment

Multiple research centers are conducting product upgrades and research and development

Technical support

Multiple research centers are conducting product upgrades and research and development

Medical field

The product is widely used in industries such as semiconductor electronics, photovoltaics, nuclear industry, aerospace, tungsten molybdenum electrodes, etc

More +Aerospace

The product is widely used in industries such as semiconductor electronics, photovoltaics, nuclear industry, aerospace, tungsten molybdenum electrodes, etc

More +Semiconductor

The product is widely used in industries such as semiconductor electronics, photovoltaics, nuclear industry, aerospace, tungsten molybdenum electrodes, etc

More +Photovoltaic industry

The product is widely used in industries such as semiconductor electronics, photovoltaics, nuclear industry, aerospace, tungsten molybdenum electrodes, etc

More +Nuclear industry

The product is widely used in industries such as semiconductor electronics, photovoltaics, nuclear industry, aerospace, tungsten molybdenum electrodes, etc

More +Vacuum coating industry

The product is widely used in industries such as semiconductor electronics, photovoltaics, nuclear industry, aerospace, tungsten molybdenum electrodes, etc

More +Medical field

Medical field

Aerospace

Aerospace

Semiconductor

Biomedicne

Photovoltaic industry

Photovoltaic industry

Nuclear industry

Nuclear industry

Vacuum coating industry

Vacuum coating industry

Creating value for customers

The patented technology has been applied to the company's products and applied in various fields

capital

Floor Area

R & D Team

Workshop area

-

U.S.A

-

Mexico

-

Columbia

-

Canada

-

Argentina

-

Brazil

-

France

-

Mali

-

Germany

-

Kenya

-

South Africa

-

India

-

Russia

-

Beijing

-

Luoyang

-

Japan

-

Australia

News

Address: China (Henan) Pilot Free Trade Zone Luoyang Area (High tech) Dongmagou Industrial Park No.1 Courtyard 1-9 Zone

E-mail:monfils.chen@mtwkj.com

Enterprise Station:http://www.mtwkj.com

Product Station:http://www.mtwxcl.com