Products

Molybdenum-copper alloy

Classification:

E-mail:

introduce

-

Product Introduction

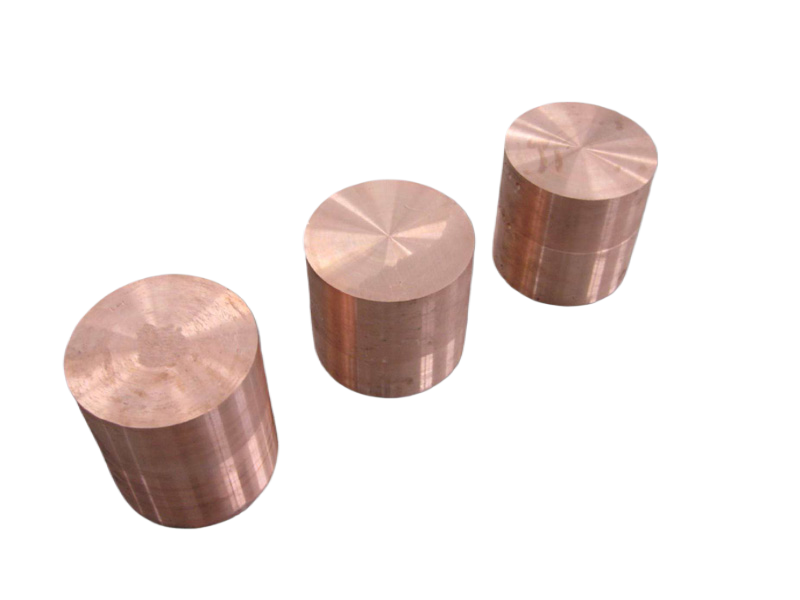

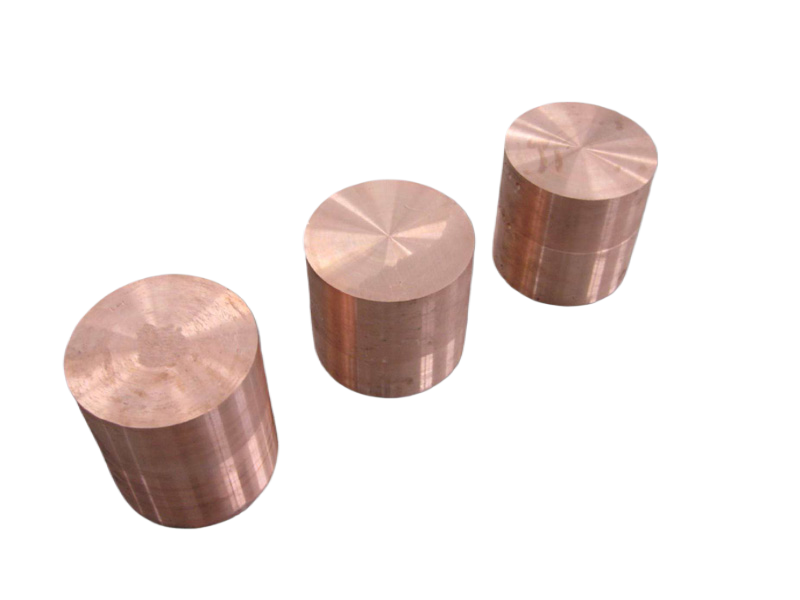

Molybdenum-copper alloy is an alloy material made of two metal elements, molybdenum and copper, through a fine process. This alloy combines the high conductivity of copper with the high strength and high melting point of molybdenum, so it has the advantages of high strength, high specific gravity, high temperature resistance, arc ablation resistance, good conductive electrothermal performance, and good processing performance.

The preparation of molybdenum copper alloy mainly adopts the melting and leaching method, through the mixing of high quality molybdenum powder and oxygen-free copper powder, the application of isostatic pressure molding (high temperature sintering-copper infiltration) process, to produce fine tissue, excellent performance of the alloy material. The alloy has good arc breaking performance, good electrical conductivity, good thermal conductivity, and small thermal expansion, so it is widely used in many fields.

In the field of electronic devices, molybdenum-copper alloys are commonly used in the manufacture of microwave connectors, relay contacts, integrated circuit substrates, etc., taking advantage of their excellent electrical conductivity and thermal conductivity. In the field of welding materials, molybdenum-copper alloys are excellent materials for electrodes, electrical contacts and other welding tools because of their high-temperature corrosion resistance and high thermal conductivity. In addition, molybdenum-copper alloys are also used in the manufacture of infrared detectors, petrochemical equipment, engine combustion chambers and nozzle components in the aerospace field, and parts of precision instruments.

Advantages of molybdenum-copper alloy

40% higher than similar tungsten-copper composites

highest thermal conductivity

Thermal and mechanical properties

thermal expansion

No need for expensive molds

High precision parts processing

Plating and metal options available

Airtight

chemical composition

Alloy grade

Cu

Mo

Total amount of impurity elements

MoCu10

10 /-2

Allowance

≤0.1

MoCu15

15 /-3

Allowance

≤0.1

MoCu20

20 /-3

Allowance

≤0.1

MoCu25

25 /-3

Allowance

≤0.1

MoCu40

40 /-5

Allowance

≤0.1

Grade parameters

Alloy grade

MoCu10

MoCu15

MoCu20

MoCu25

MoCu40

thermal conductivity

≥ 150

≥ 160

≥170

≥ 180

thermal expansion rate

5.6 /-1.5

6.7 /-1.5

7.4 /-1.5

7.9 /-2

8.0 /-3

Alloy grade

MoCu10

MoCu15

MoCu20

MoCu25

MoCu40

Density

≥ 9.91

≥ 9.83

≥ 9.75

≥ 9.70

≥ 9.3

Molybdenum Copper Alloy Application

-

Electronic devices: Molybdenum-copper alloys are commonly used as heat sinks and substrates for high-performance electronic devices. Due to its good thermal conductivity and mechanical strength, it can effectively conduct heat to the surrounding environment and maintain the stable performance of electronic devices.

-

Vacuum equipment components: molybdenum copper alloy has a wide range of applications in vacuum equipment, such as vacuum tubes, vacuum valves, vacuum seals, etc. Its high melting point and good corrosion resistance enable it to work stably in high vacuum environment.

-

Aerospace field: Because of the high strength, corrosion resistance and high temperature resistance of molybdenum copper alloy, it is often used in the manufacture of structural parts, thermal controls and wear-resistant parts of aerospace devices.

-

Chemical industry: Molybdenum-copper alloys also have certain applications in the chemical industry, such as the manufacture of corrosion-resistant reaction vessels, pipelines, valves and other equipment, as well as accessories for the manufacture of high-temperature, high-pressure catalysts and reactors.

-

Power industry: molybdenum copper alloy is often used in the manufacture of high-performance power conduction lines, grounding wires and electrical connectors and other components to ensure the stability and safety of the power system.

-

Military field: Because molybdenum-copper alloy has good wear resistance and corrosion resistance, it is often used to manufacture key components of military equipment, such as missile parts and aircraft structural parts.

-

Key words:

Molybdenum-copper alloy

Previous Page:

Next page:

Product Message

Address: China (Henan) Pilot Free Trade Zone Luoyang Area (High tech) Dongmagou Industrial Park No.1 Courtyard 1-9 Zone

E-mail:monfils.chen@mtwkj.com

Enterprise Station:http://www.mtwkj.com

Product Station:http://www.mtwxcl.com