Products

Tungsten-molybdenum alloy

Classification:

E-mail:

introduce

-

Product Introduction

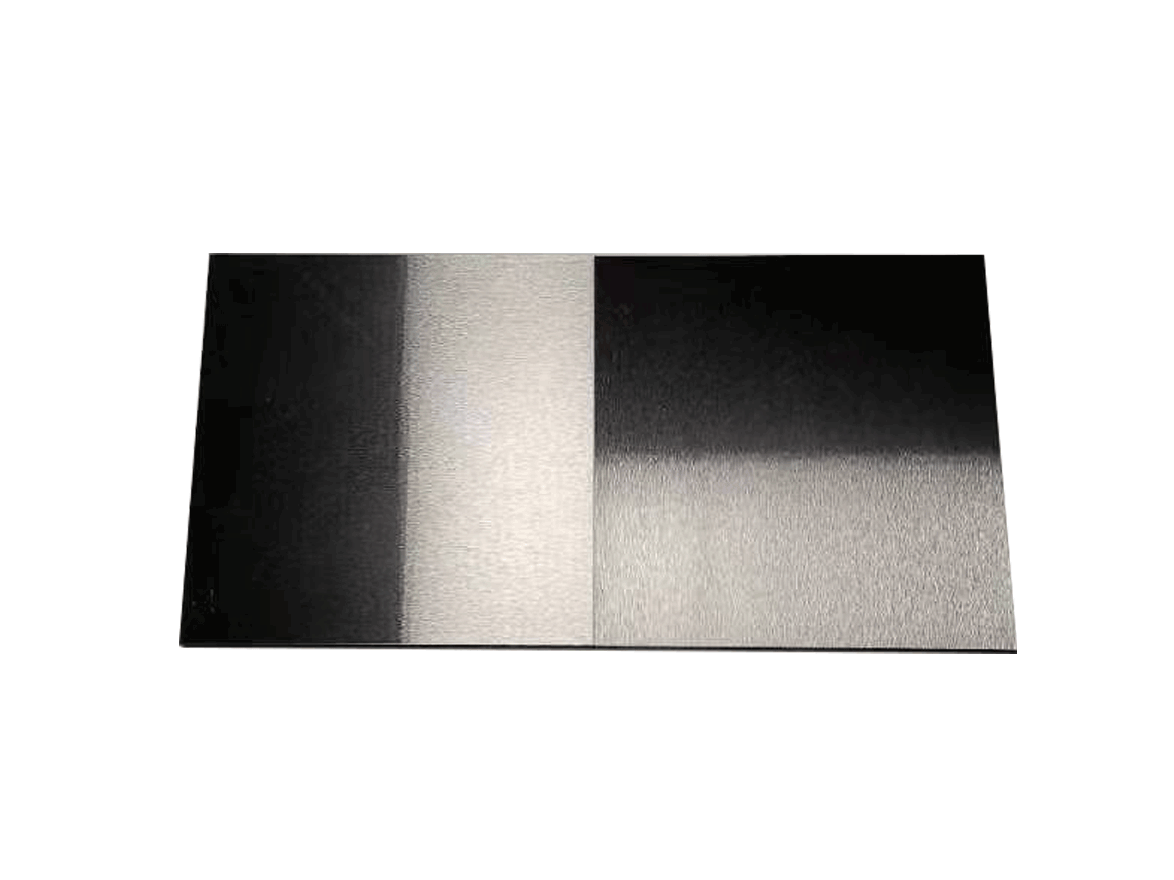

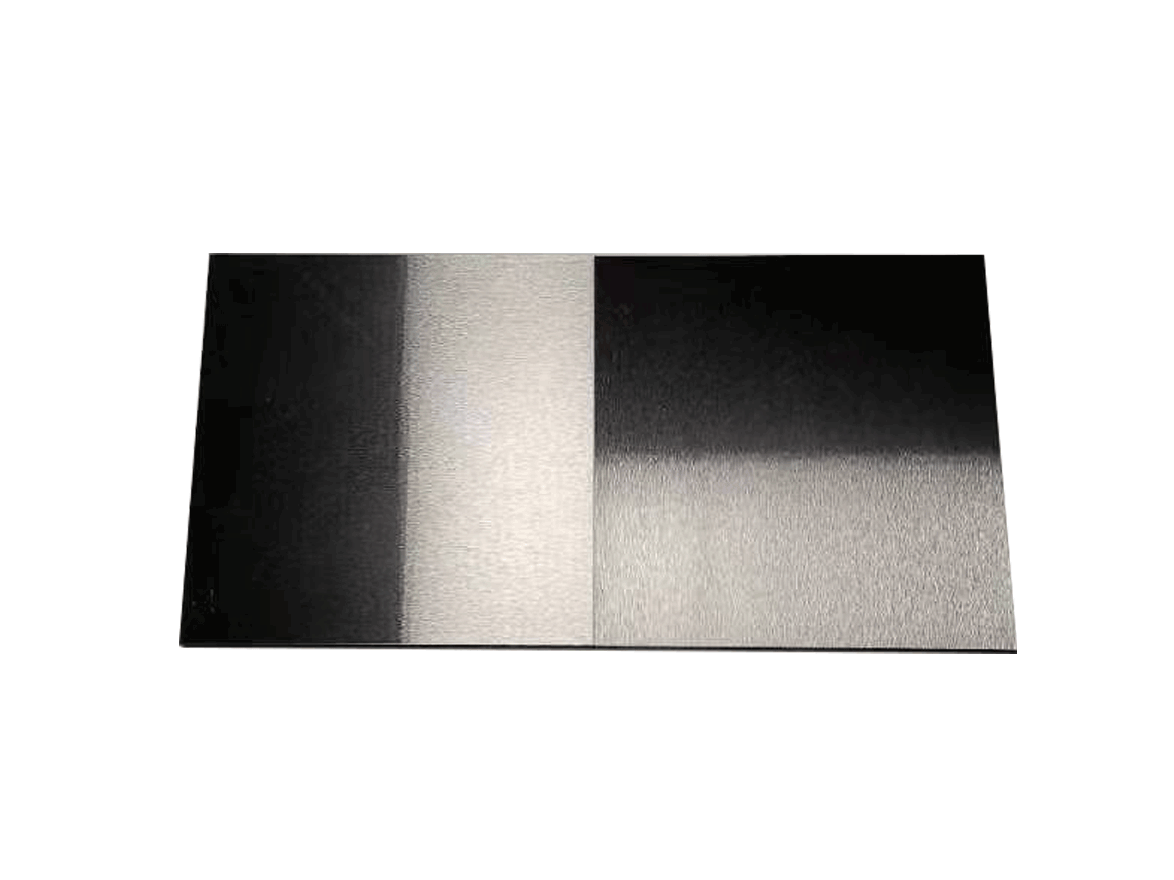

Tungsten-molybdenum alloy refers to an alloy composed of tungsten and molybdenum, in which the tungsten content in the commonly used tungsten-molybdenum alloy is 30% to 50% (mass). The preparation method of tungsten molybdenum alloy is the same as that of metal molybdenum and molybdenum alloy, mainly including powder metallurgy sintering post-processing and smelting processing, which can be used to make rods, plates, wires or other profiles. The properties of tungsten-molybdenum alloys change with the increase of tungsten content. For example, the melting point of molybdenum-tungsten alloy increases with the increase of tungsten content. When the tungsten content increases to 25%, the melting point of the alloy is about 200 ℃ higher than that of pure molybdenum. In addition, the lattice constant and density of the molybdenum-tungsten alloy increase as a linear function with the increase of tungsten content, and the hardness and strength also increase with the increase of tungsten content. The highest room temperature hardness value of the alloy is between 90% and 100, and its Vickers hardness value is as high as 3530 ~ 3860MPa, which is more than double that of pure molybdenum.

Main characteristics

High melting point and high thermal stability: Tungsten and molybdenum are both high melting point metals. The melting point of tungsten is about 3422°C, while the melting point of molybdenum is about 2623°C. As a result, tungsten-molybdenum alloys have extremely high melting points, which makes them perform well in high-temperature environments, such as those used in rocket engines, jet engines, and other high-temperature equipment.

Good high temperature strengthTungsten molybdenum alloy can still maintain good mechanical properties at high temperature, such as strength, hardness and toughness. This allows them to withstand large loads and impacts under high temperature conditions.

Excellent corrosion resistance: Tungsten-molybdenum alloy has good resistance to a variety of corrosive media, such as acid, alkali, salt, etc. Therefore, they are often used to manufacture corrosion-resistant equipment, chemical equipment and components in marine engineering.

Good thermal and electrical conductivityTungsten-molybdenum alloys have good thermal conductivity and electrical conductivity, which makes them widely used in electronic devices, vacuum tubes, heating elements and other fields.

Low coefficient of thermal expansion: The thermal expansion coefficient of tungsten-molybdenum alloy is relatively low, which helps to maintain the dimensional stability of the parts at high temperatures.

Good processing performance: Although tungsten-molybdenum alloys have high hardness, they can still be processed into products of various shapes and sizes through appropriate processing methods (such as powder metallurgy, forging, rolling, drawing, etc.).

Solderability and ConnectabilityTungsten-molybdenum alloys can be connected by appropriate welding and joining techniques, which makes them more flexible when manufacturing complex structures and components.

High oxidation resistance: Tungsten-molybdenum alloy has good oxidation resistance at high temperature and can resist oxygen erosion.

High density: Tungsten-molybdenum alloys have a high density, which makes them advantageous in applications that require high-density materials (such as radiation shielding, counterweights, etc.).

Application areas

- Energy field:

In the field of nuclear energy: Tungsten-molybdenum alloys have a wide range of applications in the field of nuclear energy, such as structural parts, control rods, and nuclear fuel elements inside nuclear power plants. Its high temperature strength, corrosion resistance and radiation resistance make it an important material in the field of nuclear energy.

Solar energy field: Tungsten and molybdenum alloys perform well in the production of solar cells, and the solar cells made have the advantages of high photoelectric conversion efficiency and long life. In addition, there are certain applications in the field of solar thermal utilization.

Wind energy field: Although the application of tungsten and molybdenum products in the field of wind energy is relatively small, its high strength and corrosion resistance make it suitable for manufacturing key components of wind turbines, such as blades and main shafts.

- Electronic areas:

Soldering electronic devices: Tungsten-molybdenum alloys have good thermal stability and low thermal expansion coefficient, so they are widely used in the manufacture of electronic devices, such as semiconductor devices, vacuum tubes, electron tubes, optoelectronic devices, such as leads, packaging and support structures.

Electronic industry: metal molybdenum is easy to be processed into wire, belt, sheet, rod, etc., and is widely used in the electronic industry. The molybdenum wire is used as a small hook to support the heating wire in the electric bulb, the grid of the electron tube, etc.

- Aerospace and Weapons Manufacturing:

Aerospace field: Tungsten-molybdenum alloys have good heat resistance, high strength and high hardness at high temperatures, and can withstand heavy loads and wear at high temperatures, so they are widely used in the aerospace field, such as the manufacture of rocket engines and other components.

Weapons manufacturing: Molybdenum and metal alloys are important in weapons manufacturing and in cutting-edge areas such as missiles and rockets.

- Other areas:

Cutting tools: Tungsten-molybdenum alloy has good cutting performance and wear resistance, so it is widely used in the manufacture of cutting tools, such as drill bits, blades, cutting wheels, etc.

Radiation protection materials: Tungsten-molybdenum alloys have good radiation protection properties, so they are widely used in the manufacture of radiation protection materials for nuclear facilities.

Key words:

Tungsten-molybdenum alloy

Previous Page:

Next page:

Product Message

Address: China (Henan) Pilot Free Trade Zone Luoyang Area (High tech) Dongmagou Industrial Park No.1 Courtyard 1-9 Zone

E-mail:monfils.chen@mtwkj.com

Enterprise Station:http://www.mtwkj.com

Product Station:http://www.mtwxcl.com