Products

Tungsten-based high specific gravity alloy

Classification:

E-mail:

introduce

-

Product Introduction

High density tungsten alloy is a kind of tungsten matrix (W content 85-99%), and add Ni, Cu, Co, Mo, Cr and other elements of the alloy.

According to the composition characteristics and uses of the alloy is divided into W-Ni-Fe, W-Ni-Cu, W-Co, W-WC-Cu, and other major series, its density is as high as 16 .5-19.0g/cm3, which is called high specific gravity alloy.

It also has a series of excellent characteristics, with large specific gravity: general specific gravity of 16.5-18.75g/cm3, high strength: tensile strength of 700-1000Mpa, strong ability to absorb rays: its ability is 30-40% higher than lead, and its thermal conductivity is large: 5 times that of die steel; Small thermal expansion coefficient: only 1/2-1/3 of iron or steel, good electrical conductivity; It has good weldability and workability.

tungsten-nickel-copper alloy

The W-Ni-Cu system generally contains 90 ~ 95% tungsten, and the ratio of nickel to copper added is generally 3:2. This kind of alloy has no ferromagnetism and relatively good electrical and thermal conductivity. It is often used in some special occasions, such as gyroscope rotors and other components of devices and instruments that require work under the action of a magnetic field; electrical contacts of high-voltage electrical switches and Some electrodes for electrical processing, etc.

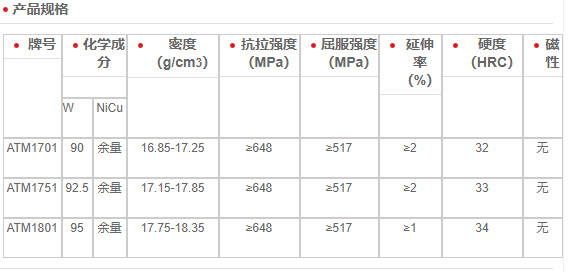

Main grades: W90NiCu(ATM1701), W93NiCu(ATM1751), W95NiCu(ATM1801).

tungsten-nickel-iron alloy

The W-Ni-Fe system generally contains 90 ~ 98% tungsten, and the nickel-iron content ratio is mostly 7:3 or 1:1. Tungsten-nickel-iron alloy is characterized by high sintering density, good strength and plasticity, and certain ferromagnetism. Good plasticity and machinability, good thermal and electrical conductivity, and excellent absorption of gamma rays or X-rays. Tungsten-nickel-iron alloy is widely used and has become the main tungsten-based heavy alloy with the largest amount. As general applications, such as counterweights, counterweights, radiation shielding devices, etc., are directly used sintered alloys; but as applications requiring high mechanical properties, tungsten-nickel-iron alloy requires deformation processing and heat treatment to achieve strengthening.

Brand

Chemical composition%

Degreaser (g/cm³)

Tensile strength (Mpa)

Yield strength (Mpa)

Modulus of elasticity (%)

Hardness Max(HRC)

Magnetic

W

NiFe

ATM1700

90

The rest

16.85-17.25

≥ 758

≥ 517

≥ 5

32

Yes

ATM1750

92.5

The rest

17.15-17.85

≥ 758

≥ 517

≥ 5

33

Yes

ATM1800

95

The rest

17.75-18.35

≥ 724

≥ 517

≥3

34

Yes

ATM1850

97

The rest

18.25-18.85

≥ 689

≥ 517

≥ 2

35

Yes

tungsten goo alloy

Tungsten cobalt alloy, also known as tungsten carbide-cobalt cemented carbide. According to the cobalt content, it can be divided into three categories: high cobalt (20% ~ 30%), medium cobalt (10% ~ 15%) and low cobalt (3% ~ 8%). This kind of metal ceramics can be manufactured according to the usual special ceramic ingredients, molding and other processes, but the firing should be based on the nature of the blank and the quality of the finished product to control the sintering atmosphere for vacuum or reduction atmosphere, generally in the carbon tube electric furnace, hydrogen molybdenum wire electric furnace, high-frequency vacuum furnace. The grades of such cemented carbide produced in China are YG2,YG3,YG3X,YG4C.

The letters "YG" represent "WC-Co", the number following "G" represents the content of Co, "X" represents fine grains, and "C" represents coarse grains. Such cermets generally increase in flexural strength and fracture toughness with increasing cobalt content, while the hardness decreases. The tungsten-cobalt alloy has high elastic modulus and small thermal expansion coefficient, and is the most widely used type of cemented carbide.

Tungsten cobalt alloy can be used as a tool to process cast iron, non-ferrous metals, non-metallic, heat-resistant alloys, titanium alloys and stainless steel, etc., and can also be used as drawing dies, wear-resistant parts, stamping dies and drills.

Product Message

Address: China (Henan) Pilot Free Trade Zone Luoyang Area (High tech) Dongmagou Industrial Park No.1 Courtyard 1-9 Zone

E-mail:monfils.chen@mtwkj.com

Enterprise Station:http://www.mtwkj.com

Product Station:http://www.mtwxcl.com