Products

Molybdenum strip

Classification:

E-mail:

introduce

-

Product Introduction

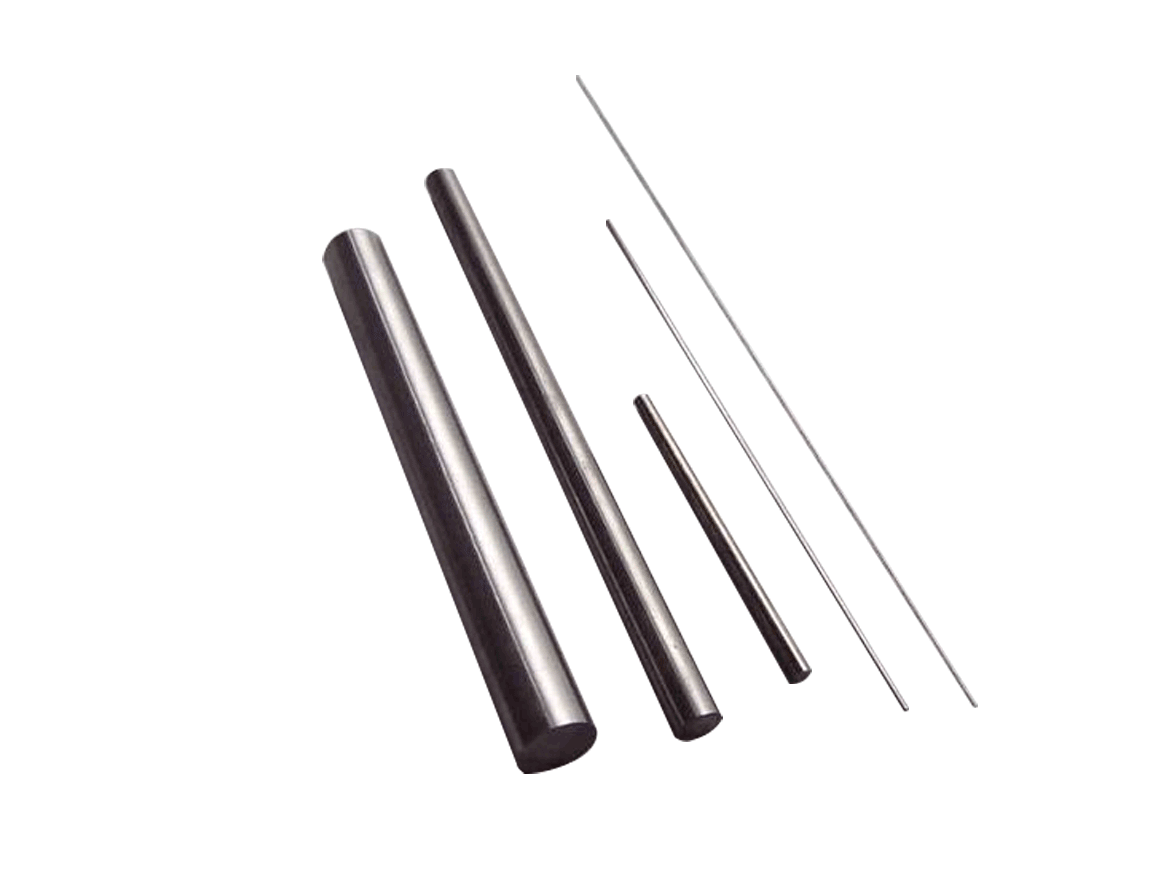

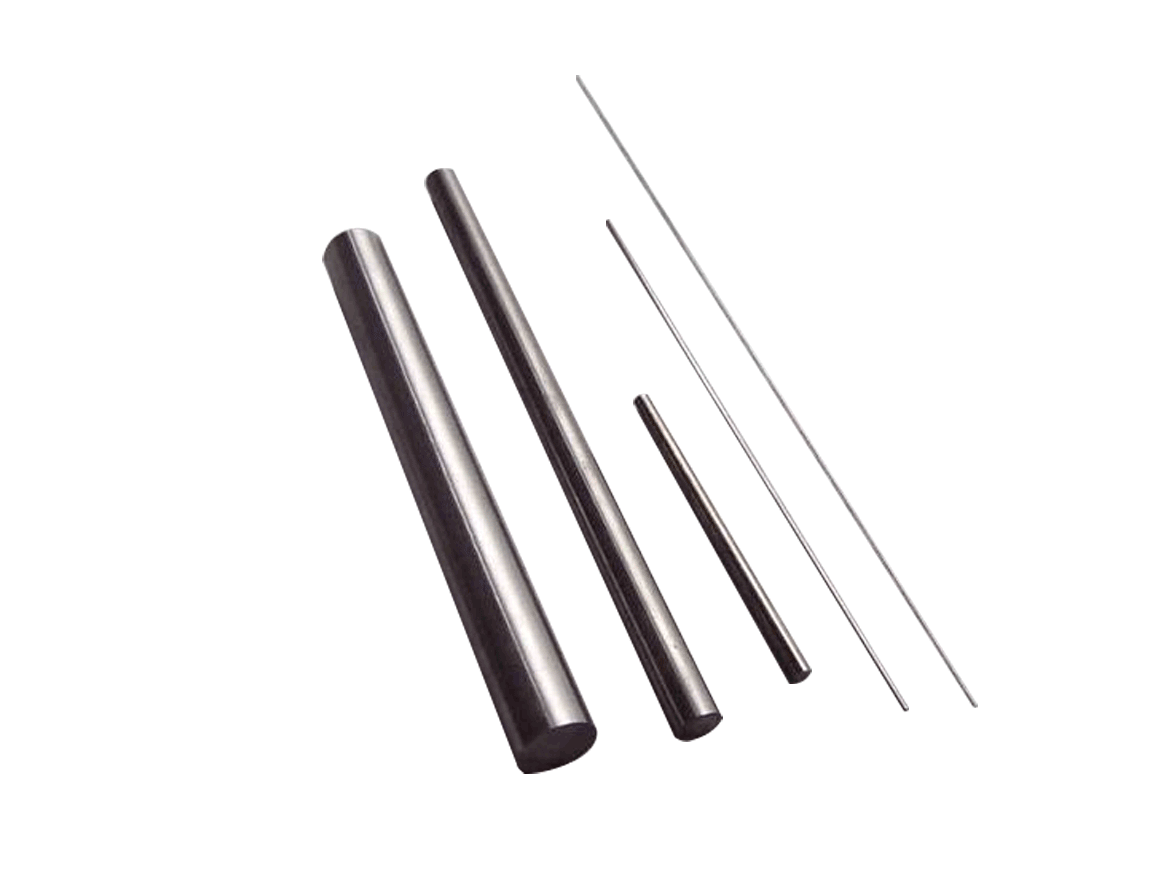

Molybdenum bar is a product made by sintering molybdenum powder with a purity of more than 99.80%. It has a silvery white appearance, bright and shiny surface, and has a high melting point, high specific gravity, high strength, high hardness, low coefficient of thermal expansion and other characteristics. These characteristics make the molybdenum bar maintain good performance under extreme conditions such as high temperature and high pressure.

From the shape, molybdenum bar can be divided into two kinds of round bar and square bar. Its common grades are Mo-1, Mo-2, Mo-3, Mo-4, etc., each grade has its specific use and physical properties. For example, Mo-1 is mainly used as an alloy additive and molybdenum-based alloy raw material, while Mo-2 and Mo-3 are more suitable as raw materials for processing materials, and Mo-4 is an additive and electrode material.

Product Features

-

High temperature resistance: Molybdenum bar has excellent high temperature resistance, its melting point is as high as 2620 ℃, and it can remain stable in high temperature environment.

-

Corrosion resistance: Molybdenum bars are stable at room temperature and exhibit good oxidation resistance and corrosion resistance even at high temperatures.

-

Thermal conductivity: Molybdenum bar has good thermal conductivity and electrical conductivity, and is suitable for manufacturing high temperature heat transfer elements and conductive materials.

-

Mechanical properties: Molybdenum bar has the characteristics of high specific gravity, high strength and high hardness, and is suitable for manufacturing various mechanical equipment and parts.

Product Application

Molybdenum bars have a wide range of applications in the industrial field, including but not limited to the following aspects:

-

Vacuum furnace heating element: Molybdenum bar is often used as the heating element of vacuum furnace. Its excellent high temperature strength and small thermal expansion coefficient can ensure the stability and uniformity of the heating environment in the furnace.

-

Tungsten-molybdenum alloy material: tungsten-molybdenum alloy material made of molybdenum bar and tungsten alloy has high melting point, high specific gravity and good corrosion resistance, and is suitable for manufacturing high-temperature workpieces, vacuum coating materials, aerospace materials, etc.

-

Semiconductor materials: Molybdenum bars are used in the semiconductor industry to prepare metal contacts, electrode materials, etc., and are important materials for the production and development of semiconductor devices.

-

Iron and steel smelting additives: A small amount of molybdenum can increase the strength and hardness of steel and improve corrosion resistance. Therefore, molybdenum bars are important additives in the smelting industry.

In general, as a high-quality metal material, molybdenum strip plays an important role in industrial production and scientific research. With the continuous progress of science and technology and the continuous development of industry, the application field of molybdenum bar will be more extensive.

-

Product Message

Address: China (Henan) Pilot Free Trade Zone Luoyang Area (High tech) Dongmagou Industrial Park No.1 Courtyard 1-9 Zone

E-mail:monfils.chen@mtwkj.com

Enterprise Station:http://www.mtwkj.com

Product Station:http://www.mtwxcl.com