Products

Molybdenum Stranded Wire

Classification:

E-mail:

introduce

-

Product Introduction

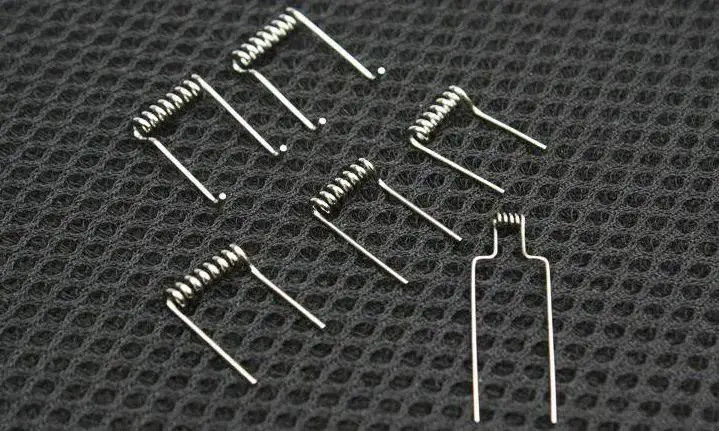

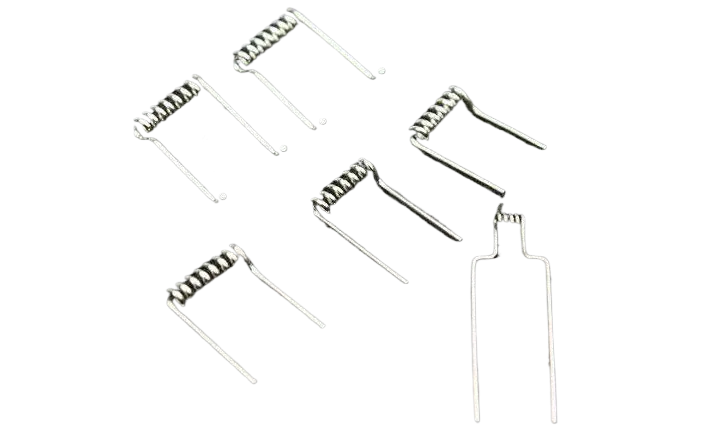

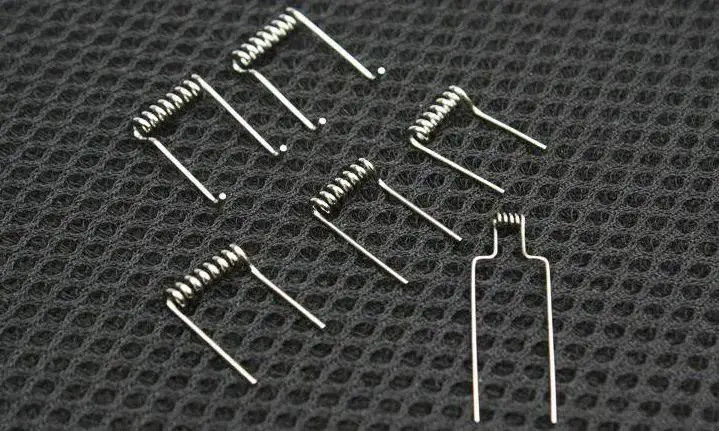

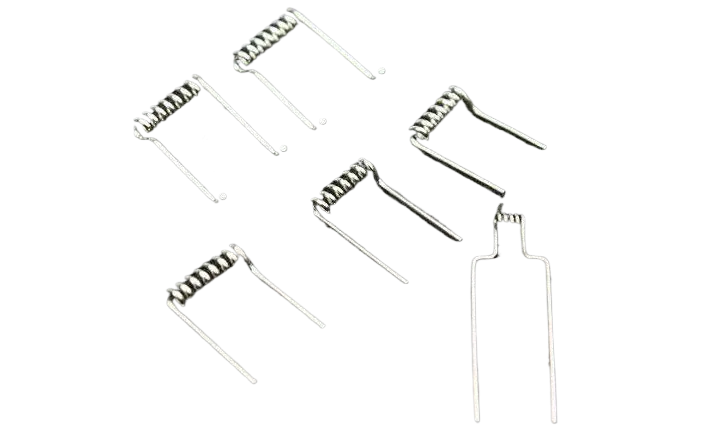

The production process mainly includes the following steps: material selection, cutting, straightening, processing thread, twisting, annealing treatment, drawing, surface treatment and testing and packaging.

Specifically, the molybdenum wire is wrapped tightly, smoothed and straightened by mechanical or manual methods, and then the twisted wire hook is rotated for a certain number of turns by mechanical power, and finally the molybdenum twisted wire with twisted twist is made. Molybdenum twisted wire has different specifications such as large twisted wire, small twisted wire and long twisted wire.

In the process of processing, it is necessary to strictly control the temperature, speed, pressure and other process parameters to ensure the quality and performance of the molybdenum strand. Molybdenum twisted wire is mainly used in vacuum coating and other fields, and is an important industrial material.

Key words:

Molybdenum Stranded Wire

Previous Page:

Next page:

Product Message

Address: China (Henan) Pilot Free Trade Zone Luoyang Area (High tech) Dongmagou Industrial Park No.1 Courtyard 1-9 Zone

E-mail:monfils.chen@mtwkj.com

Enterprise Station:http://www.mtwkj.com

Product Station:http://www.mtwxcl.com