Products

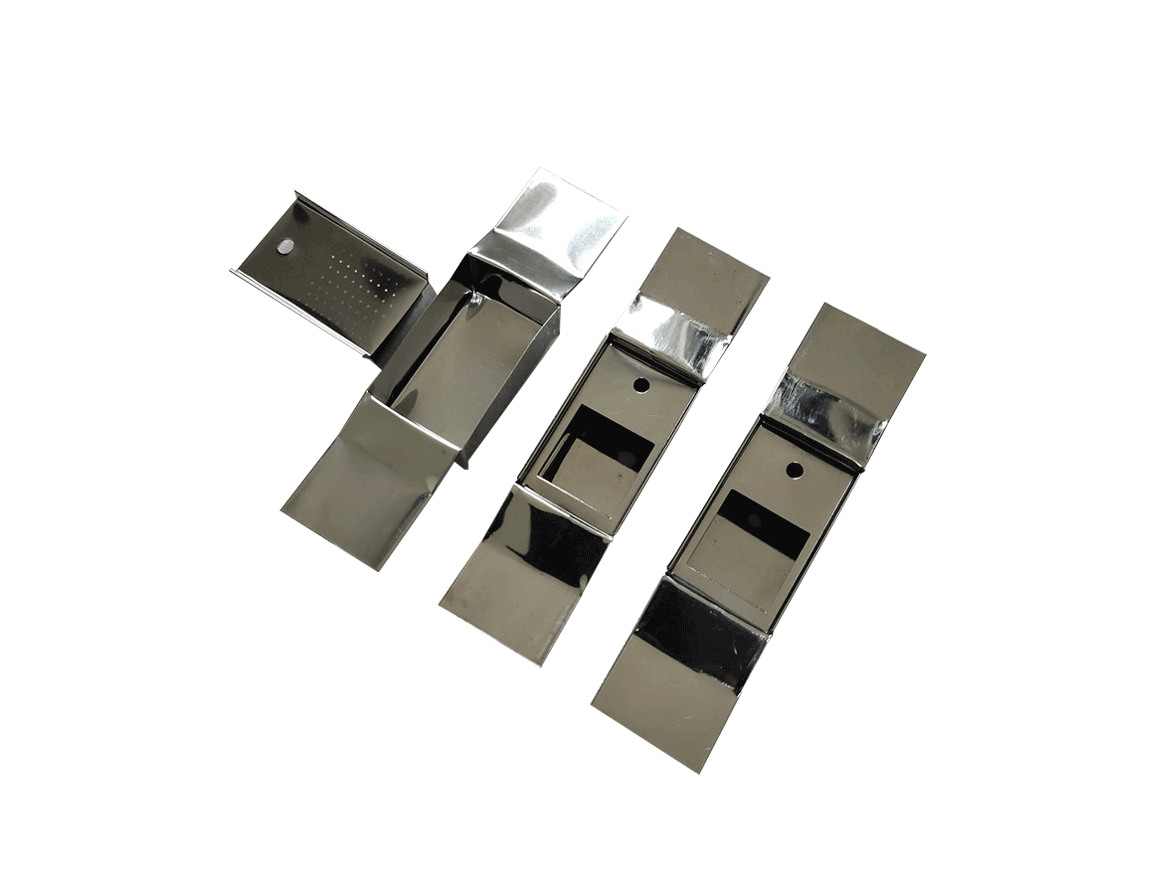

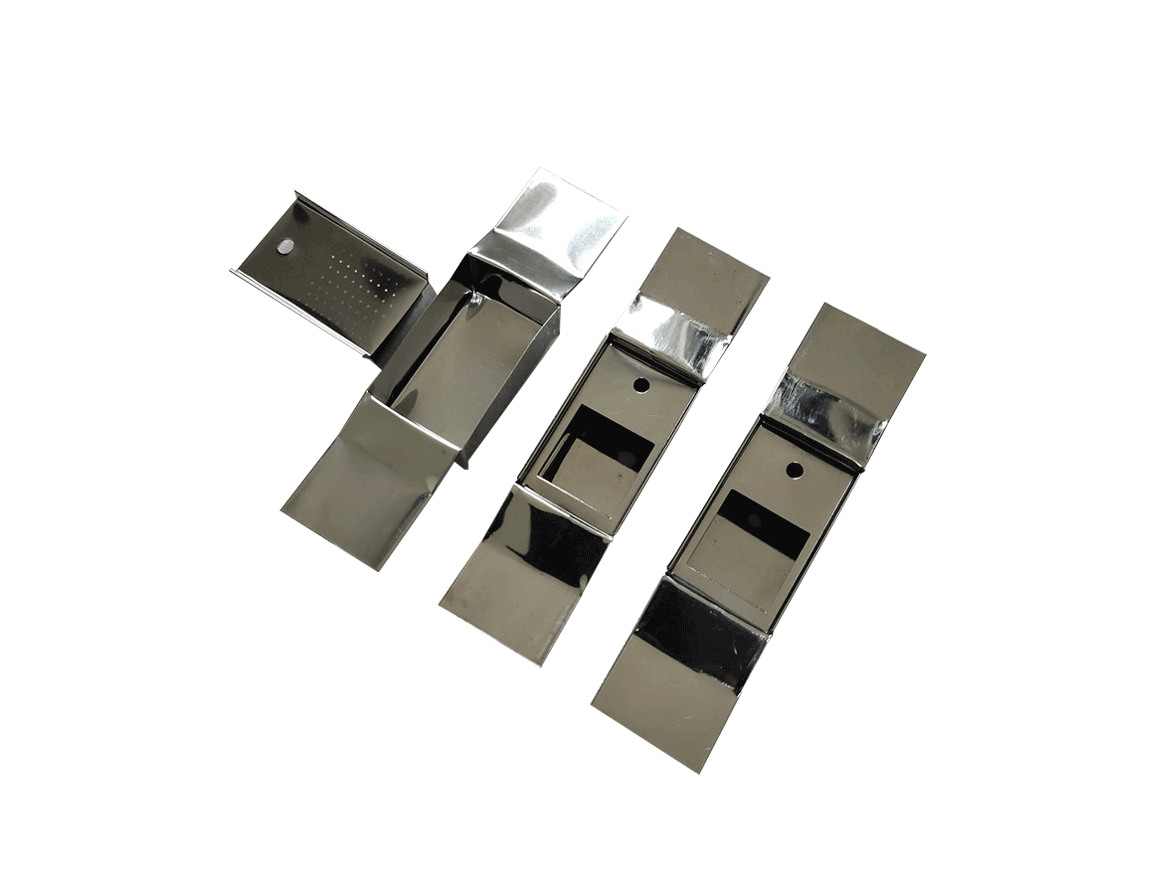

Molybdenum boat

Classification:

E-mail:

introduce

-

Product Introduction

Brand: Mo1, MoLa, TZM

Purity: ≥ 99.95%

密度:10.2g/cm³

Molybdenum boat is a kind of molybdenum products, it is also often called evaporation molybdenum boat or coated molybdenum boat, is a kind of high temperature vessel. Molybdenum boats are made of molybdenum sheets by high-temperature stamping. They are divided into different types according to different processing methods, including stamping boats, folding boats, welding boats and riveting boats. It has good electrical conductivity, thermal conductivity, high temperature resistance, corrosion resistance and wear resistance, so it is mainly used in coating technology, electronic industry, power engineering and other fields, such as capacitor sintering, vacuum thermal evaporation, nuclear fuel sintering, thermocouple shell Wait.

Material characteristics

High melting point (2623°C)

low thermal expansion rate

high thermal conductivity

low vapor pressure

Excellent resistance to molten metal and glass corrosion

Classification of Molybdenum Boat

1. Flat groove molybdenum boat: suitable for high wettability materials;

2. V-shaped groove molybdenum boat: suitable for materials with small wettability;

3. Oval groove molybdenum boat: suitable for materials in molten state;

4, spherical groove molybdenum boat: suitable for gold, silver and other expensive materials;

5. Narrow groove molybdenum boat: This design can prevent evaporation material from getting into the filament clamp;

6. Steamed aluminum boat: the surface of the boat body is plated with a layer of aluminum oxide to help the evaporation boat resist particularly corrosive molten materials.

Widely used

-

Molybdenum boat for vacuum coating industry

-

High-temperature vacuum furnace or gas-protected furnace carrying boat box

-

Bearing boat for sintering of magnetic materials

-

nuclear industry carrier boat

high temperature sintered molybdenum boat

High temperature sintered molybdenum boat is mainly used in vacuum furnace, its use temperature can reach about 1700-2000 ℃, mainly in the molybdenum powder doped with a certain amount of rare earth elements, improve the high temperature strength of molybdenum, expand the scope of use of molybdenum boat. At present, the molybdenum boat used in the vacuum furnace industry generally has two kinds of materials: one is the molybdenum boat produced by pure molybdenum, which can reach about 1100 degrees high temperature resistance, and is used as a melting vessel for smelting rare earth materials and sintering tungsten oxide. The second is the molybdenum alloy boat produced by molybdenum lanthanum alloy and TZM alloy, which is used to meet the needs of higher temperature, and the high temperature resistance can reach about 1700-2000 degrees. The preparation process of the molybdenum boat: by bending a molybdenum plate with a thickness of 3-6mm, and then using welding and riveting to make the molybdenum boat, generally called welded molybdenum boat and riveted molybdenum boat.

The use of molybdenum boat: Mainly used in coating technology, electronic industry, power engineering, such as vacuum thermal evaporation (stamping evaporation boat), capacitor sintering, nuclear fuel sintering, thermocouple shell, etc. In fact, it is a kind of high temperature resistant vessel, which is used in vacuum furnace and glass melting furnace. Compared with molybdenum crucible, it has simple structure and low cost. Molybdenum boats are often used in high-temperature heat treatment industries, such as vacuum furnaces, ammonia furnaces, industrial furnaces and other high-temperature furnaces as material melters.

Molybdenum box

Molybdenum box (molybdenum boat) has good high temperature performance, thermal conductivity and corrosion resistance, commonly used in high temperature conditions, mainly as a high temperature vessel for sintering tungsten oxide. In addition to being used as a vessel for sintering tungsten oxide, it is also widely used in vacuum coating industries such as gold plating, evaporators, picture tube mirrors, heating containers, electron beam painting, household appliance shells, mobile phones, toys, and tracking decorations, and sintering furnaces. In the ship industry of sintering or vacuum annealing. Under vacuum or dry conditions, the wires are connected at both ends of the molybdenum boat and energized, and the low melting point metal is placed in the middle recess. When the temperature rises to 2000 ℃, the metal will evaporate into gas and plate on the workpiece. According to the different processing methods, the molybdenum box can be divided into sintered molybdenum box, riveting molybdenum box, stamping molybdenum box and so on.

-

Product Message

Address: China (Henan) Pilot Free Trade Zone Luoyang Area (High tech) Dongmagou Industrial Park No.1 Courtyard 1-9 Zone

E-mail:monfils.chen@mtwkj.com

Enterprise Station:http://www.mtwkj.com

Product Station:http://www.mtwxcl.com