Products

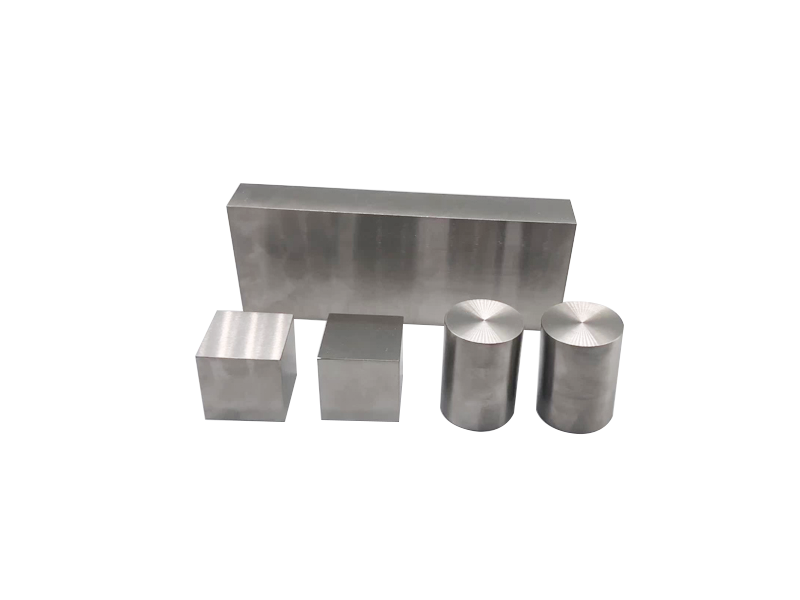

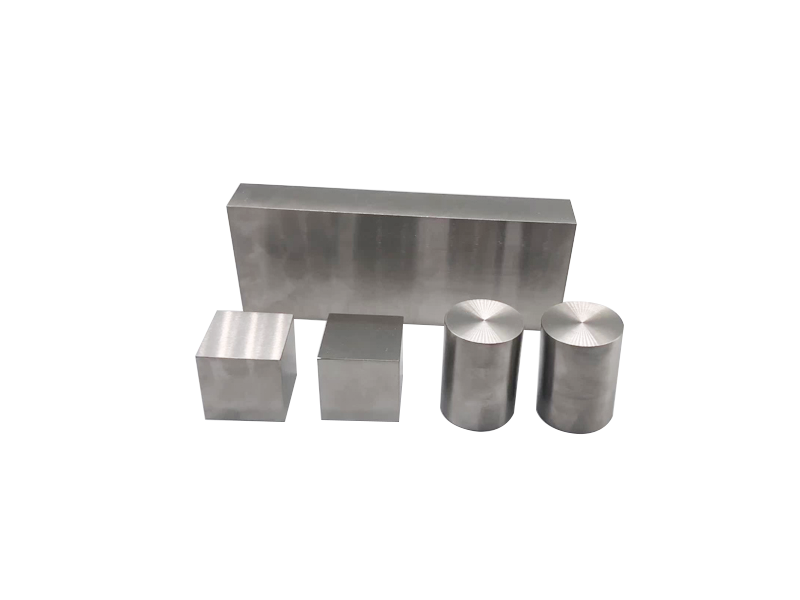

Tungsten Nickel Alloy

Classification:

E-mail:

introduce

-

Product Introduction

Tungsten-nickel alloy is an alloy material with unique physical and chemical properties, which is characterized by high melting point, high hardness and high corrosion resistance. The nickel content of tungsten nickel alloy is usually less than 10% or between 10% and 25%, and the rest is mainly tungsten.

Tungsten-nickel alloy has good high temperature strength and corrosion resistance, which makes it have a wide range of applications in many fields. For example, in the aerospace field, tungsten-nickel alloys are often used to make parts for aircraft and satellites because they need to maintain stable performance in extreme high temperature environments. In addition, the high hardness and good processing performance of tungsten nickel alloy also make it widely used in the field of manufacturing cutting tools and molds.

In order to produce tungsten-nickel cemented carbide with stronger acid and alkali resistance and non-magnetic properties, researchers proposed a new preparation method, which involves specific raw material ratios and preparation steps, such as mixing ball milling, pressing molding and vacuum furnace sintering.

Although tungsten-nickel alloys have many advantages, it is important to note that nickel metals and nickel alloys are classified as Class 2B carcinogens in the list of carcinogens of the World Health Organization's International Agency for Research on Cancer. Therefore, appropriate safety measures should be taken when handling and using tungsten-nickel alloys.

Key words:

Tungsten Nickel Alloy

Previous Page:

Next page:

Product Message

Address: China (Henan) Pilot Free Trade Zone Luoyang Area (High tech) Dongmagou Industrial Park No.1 Courtyard 1-9 Zone

E-mail:monfils.chen@mtwkj.com

Enterprise Station:http://www.mtwkj.com

Product Station:http://www.mtwxcl.com