Products

Tungsten machined parts

Classification:

E-mail:

introduce

-

Unique properties of tungsten

Tungsten, also known as Tungsten, is a rare metal element with a melting point of 3,410°C. This extremely high heat resistance combined with incredible hardness makes it an ideal material for high temperature, high pressure and high wear applications. In addition to its impressive physical properties, tungsten also has excellent corrosion resistance and electrical conductivity. These properties make it a popular material in industries such as aerospace, defense, automotive and electronics.

Challenges of Machining Tungsten

Machining tungsten is not an easy task. Its high hardness and density make it difficult to cut, grind and shape using traditional processing methods. In addition, the inherent brittleness of tungsten can lead to chipping and cracking during processing. To overcome these challenges, we turned our focus on machining tungsten to CNC machining-a process that enables the precise production of tungsten parts.

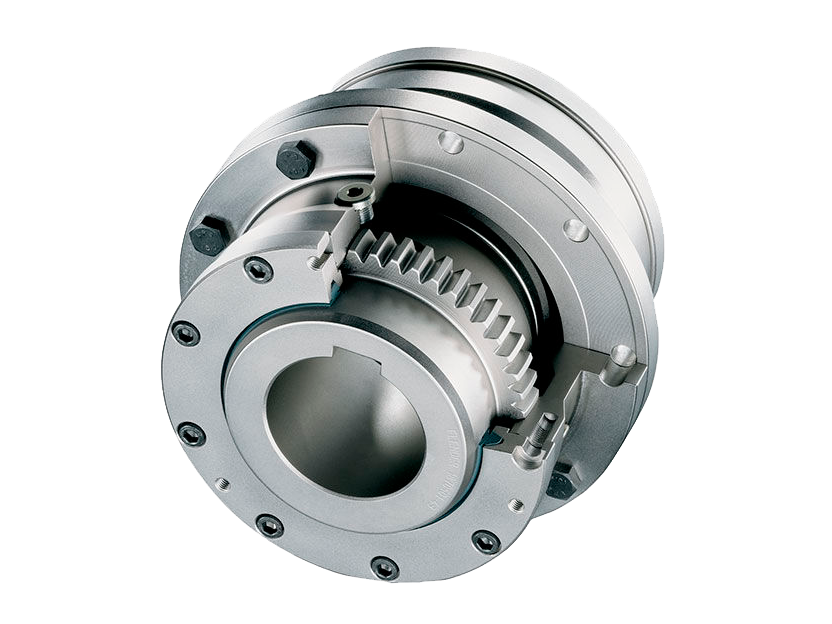

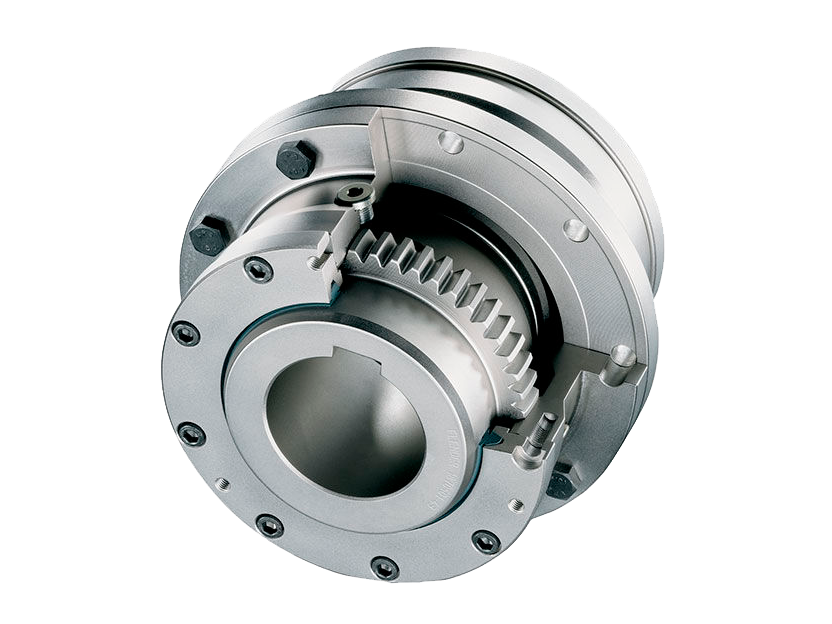

The process of CNC machining tungsten parts

CNC (computer numerical control) machining is a subtractive manufacturing process that uses a computer-controlled machine tool to remove material from a workpiece and ultimately produce the desired part. The process starts with a digital 3D model of the part, which is then converted into a series of machine-readable instructions to guide the actions of the CNC machine.

When machining tungsten parts, CNC machines must be equipped with special cutting tools made of materials such as polycrystalline diamond (PCD) or cubic boron nitride (CBN). These tools can withstand the forces and temperatures generated when cutting tungsten, ensuring a smooth and precise machining process.

The machining process of CNC tungsten parts usually involves several stages, including milling, turning, grinding and polishing. Each stage needs to be carefully controlled to maintain tight tolerances and ensure that the final part meets the required specifications.

Advantages of CNC Machining Tungsten Parts

Precision: CNC machines can produce parts with extremely tight tolerances, ensuring that the final product meets the exact specifications required for the application.

Efficiency: Based on the nature of mechanical automation, CNC machining can quickly produce parts, shorten delivery time as much as possible and reduce overall costs.

Flexibility: CNC machines can be easily reprogrammed to produce different parts, making them ideal for producing small batches or prototypes.

4. Consistency: The nature of computer control CNC machining can ensure that every part produced is the same, thereby eliminating the risk of human error and ensuring consistency of quality throughout the production process.

Product use

Tungsten's unique properties make it an ideal material for a wide range of applications, especially in industries where severe temperatures, pressures and wear resistance are required. Some CNC machined tungsten parts include:

Aerospace: Tungsten components can withstand severe temperatures and pressures, so they can be used in aircraft engines, rocket nozzles and heat shields.

Defense: Tungsten is used in armor-piercing shells, missile components, and radiation shielding because of its incredible hardness and density.

▲ Automotive: High-performance engines and turbochargers use tungsten parts to improve their heat resistance and durability.

Electronics: Tungsten's excellent electrical conductivity makes it a popular choice for components for high-voltage applications, such as power semiconductors and electrical contacts.

Medical: Tungsten's high density and radiation shielding capabilities make it an ideal material for components in medical imaging equipment such as X-ray and CT scanners.

Product Message

Address: China (Henan) Pilot Free Trade Zone Luoyang Area (High tech) Dongmagou Industrial Park No.1 Courtyard 1-9 Zone

E-mail:monfils.chen@mtwkj.com

Enterprise Station:http://www.mtwkj.com

Product Station:http://www.mtwxcl.com