Products

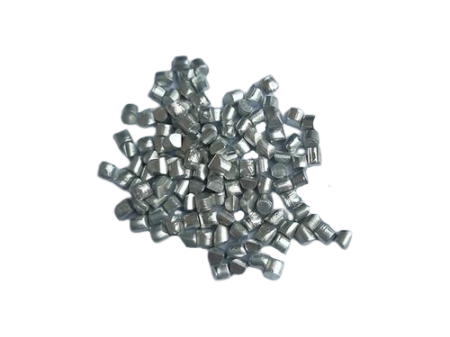

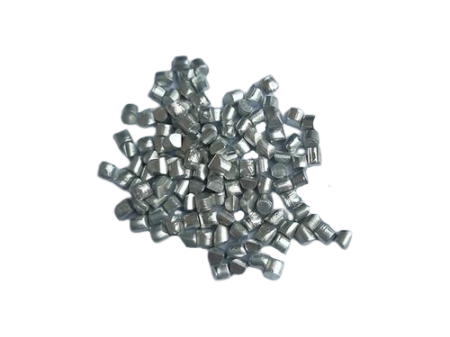

Tungsten grain

Classification:

E-mail:

introduce

-

Preparation method

The preparation methods of tungsten particles mainly include plasma method and hydrogen reduction method. Plasma method is the use of high-frequency power discharge plasma arc as a heat source, so that the metal tungsten vaporization evaporation, and then the collector cooling condensation, so as to produce nano metal tungsten powder. The hydrogen reduction law is based on APT as raw material, under the conditions of high temperature, wet hydrogen, weak reduction to produce good quality purple tungsten, purple tungsten and then through the reduction furnace under the appropriate process conditions to prepare ultrafine nano-tungsten powder.

Product use

The main uses of tungsten particles include as a flux for high-frequency combustion in high-frequency infrared carbon and sulfur analyzers. It has a good fluxing effect and makes the analysis results very stable. In addition, tungsten particles are also widely used in the manufacture of high-temperature alloys and hard alloys, such as melting point alloys, large specific gravity alloys, hard alloys and alloy additives. Tungsten particles are also suitable for processing ion injection parts, manufacturing photoelectric source and electric vacuum parts, used as high temperature heating element and high temperature structural parts, and used as electrode in rare earth industry or tungsten electrode for resistance welding, touch welding machine, argon arc welding, etc.

Product Message

Address: China (Henan) Pilot Free Trade Zone Luoyang Area (High tech) Dongmagou Industrial Park No.1 Courtyard 1-9 Zone

E-mail:monfils.chen@mtwkj.com

Enterprise Station:http://www.mtwkj.com

Product Station:http://www.mtwxcl.com